The 45-Second Trick For 24hr Media

The 45-Second Trick For 24hr Media

Blog Article

Getting The 24hr Media To Work

Table of ContentsHow 24hr Media can Save You Time, Stress, and Money.Getting My 24hr Media To Work6 Simple Techniques For 24hr MediaSome Of 24hr MediaSome Known Factual Statements About 24hr Media

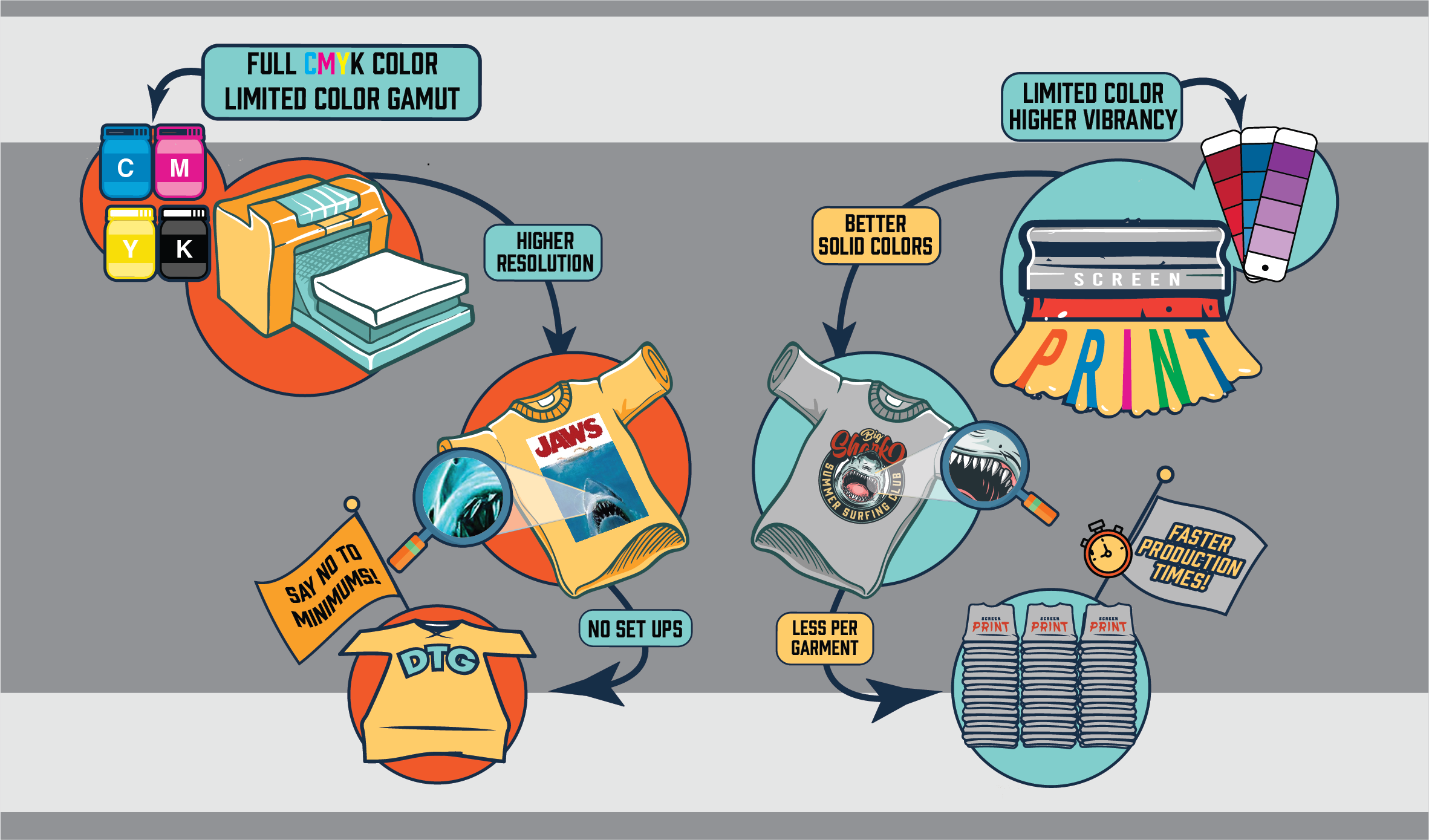

Offset, gravure printing and flexography are the most usual kinds of conventional printing in the product packaging area and each includes moving the image from a plate to the surface area. To do this, first home plate requires to be created, and it is the creation of these plates that take some time, and cost money.According to PMMI, electronic printing allows brands and makers to respond swiftly to client needs while improving the supply chain, reducing warehousing cost and waste, and appreciating faster time to market. That all noises great, yet exactly how does this technology do all that? The major differentiator of these innovations is that there are no set up fees and no plates with electronic printing.

According to Wikipedia, the greatest distinction between electronic printing and standard methods such as lithography, flexography, gravure, or letterpress is that there is no need to change printing plates in digital printing, whereas in these analog printing approaches home plates are continuously changed. This leads to quicker turn-around time and lowers cost when utilizing digital printing.

Rapid manufacturing indicates obtaining your item to market quicker. It also indicates it's simpler and faster to make adjustments in the future, when you alter a recipe, add a SKU, or develop seasonal packaging. Digital printing is highly flexible, so it's very easy to make adjustments to the bundle style rapidly. Everything goes back to the plates.

The smart Trick of 24hr Media That Nobody is Talking About

With conventional printing techniques, short-run printing is just not possible. Because a fantastic design can make or damage your product, electronic printing constantly develops high-quality, clear and vibrant graphics each time.

Filling ... Are you knowledgeable about the advantages of digital printing? Check out on to understand when electronic printing can be the best possible remedy for your business. Do you recognize why electronic printing has become the favorite option of some services? Both balanced out and electronic printing have their area in the printing industry.

In this article, we will go over the benefits of digital printing to assist you much better understand if digital printing is just what you need. Put simply - electronic printing prints product directly onto the paper. It eliminates some actions needed in countered printing, like producing steel plates. Inkjet printers make use of small nozzles to spray droplets of ink onto the substrate.

24hr Media Can Be Fun For Everyone

As electronic printing frequently advances, it uses more possibilities and greater outcome high quality each day. In many cases, the print high quality can be as high regarding balance out printing. As years go by, electronic print is ending up being a lot more easily accessible, with improved speed and top quality. This is simply the factor printing business are adding electronic printing to their offer.

For countered printing, if any type of blunder goes unnoticed before creating the plates, there will certainly be a high expense of creating a brand-new one. With electronic printing, this is not the instance (Custom Boxes). Although everyone constantly really hopes there will be no blunders, recognizing the expense of fixing them if they take place is always an excellent idea.

This means each and every single piece will look the same, so the opportunity you will require to throw out any of them because of disparities is reduced. Considering that a proofing example is printed on the exact same machine as the item itself, shade proofing is extremely accurate. Any troubles with shade will certainly be noticeable on the proof, and therefore it will certainly be feasible to change it before publishing the whole run.

24hr Media Fundamentals Explained

Digital printing, on the various other hand, requires very little configuration. This is wonderful when you are in a rush to get your printed products.

This implies more requests for electronic on-demand print production. Every customer values a customized message. One of the advantages of electronic printing is that tailoring your marketing materials navigate here couldn't be much easier. Cost-effective, smaller sized batches permit companies to customize each order. Have a back-to-school sale? Make a leaflet to target moms and dads and another one to target the students.

Digital printing is the best choice for variable information printing, like customized codes and addresses on direct mail. With digital printing, it is less bothersome to make last-minute adjustments to your style.

24hr Media Can Be Fun For Everyone

There is also no requirement to cleanse home plates after printing. The benefits of digital printing include that there is no waste from extra or leftover ink, paper, or chemicals since only what's required gets printed. - for really brief runs, digital printing is the means to go, undeniably.

Gone are the days of intricate configurations and long turn-around times - digital printing has actually changed the print market. The printing world has come a lengthy method because the days of Gutenberg's printing machine. The brand-new normal is structured processes and cost-efficient options for publishing onto nearly anything you can assume of.

Report this page